Flooring Load Ratings – PSI and Weight Limits

When choosing flooring, knowing the load ratings is important to keep it safe and long-lasting. When working with brands such as Armstrong Flooring, it’s important to understand the weight limit-measured in PSI-of access floor systems, especially in commercial areas that might need to hold the weight of a semi-trailer. This article explains why load ratings are important and how companies like Prolam and Waxin meet industry standards. This information will help you make good decisions for your flooring projects.

Key Takeaways:

Contents

- Learning About PSI (Pounds per Square Inch)

- Weight Limits in Flooring

- Types of Flooring and Their Load Ratings

- Floor Load Capacity Statistics

- Regulatory Standards and Guidelines

- Practical Applications of Load Ratings

- Frequently Asked Questions

- What is a flooring load rating in PSI?

- How are flooring load ratings in PSI determined?

- What is the weight limit for flooring with a load rating of 1000 PSI?

- What is the difference between a flooring load rating in PSI and a weight limit?

- Why is it important to consider flooring load ratings in PSI when selecting flooring for commercial or industrial spaces?

- How can I find out the flooring load rating for a specific type of flooring?

Definition of Load Ratings

Load ratings indicate the maximum weight a flooring system can support, which is critical for preventing structural failures.

These ratings are determined through standardized testing methods, such as those outlined by the American National Standards Institute (ANSI).

For instance, Armstrong Flooring’s specifications detail how different materials like vinyl or laminate can handle specific loads, typically ranging from 20 to 200 pounds per square foot.

Check the manufacturer’s instructions for load limits before installing to keep it safe and long-lasting.

Always consult with a structural engineer if you’re unsure about your floor’s load capability regarding intended use.

Why Knowing PSI and Weight Limits Matters

Knowing PSI and weight limits helps in choosing the right flooring for different uses, making sure it is safe and meets regulations.

Choosing the right flooring involves assessing factors like usage, weight distribution, and potential impact forces.

For example, in a gym, rubber flooring with a PSI of 50+ is ideal for absorbing shock from heavy weights, while a commercial kitchen may require epoxy flooring, which has a lower PSI but is resistant to water and slips.

Always check the manufacturers’ specifications and perform load tests to confirm that the flooring can support the expected weight. This preventative approach minimizes risks of damage and accidents, ensuring a safe environment for all activities.

Learning About PSI (Pounds per Square Inch)

PSI, or pounds per square inch, is an important measurement that indicates how much weight flooring materials can support. For those considering renovations, our expert opinion on attic conversion flooring provides valuable insights into managing weight and structure effectively in such projects.

What is PSI?

PSI measures the pressure exerted by a load on a given area, directly influencing the performance of different flooring systems.

In flooring applications, PSI indicates how well a material can withstand weight and stress. Concrete usually has a high PSI, which makes it suitable for heavy loads in industrial areas; it can support approximately 3,000 to 5,000 PSI.

Conversely, laminate flooring generally has a lower PSI tolerance, often suitable for residential use with lighter loads. Knowing PSI is important when choosing the right flooring to make sure it lasts, especially in busy or heavily used areas.

How PSI is Measured

PSI is usually measured by machines that test pressure on flooring samples until they break, giving exact load ratings.

Before performing the test, make sure the samples are ready following ASTM D198.

Use pressure gauges like the Ashcroft 1009, known for its accurate readings, for this kind of evaluation.

Once the sample is placed in the machine, incrementally increase pressure while monitoring the readings closely. The point at which the material fails indicates its PSI level.

Save the information to use later or to compare with other data. This method checks strength and meets industry standards.

Factors Affecting PSI Ratings

PSI ratings can change a lot based on what materials are used, how weight is spread out, and the surrounding conditions.

For example, woodcore panels tend to have a lower PSI rating compared to steel panels, due to their inherent flexibility. Armstrong Flooring provides woodcore options like the Luxe Plank, usually having a PSI of 500, which is appropriate for home use.

In contrast, steel panels, such as the Metalworks line, frequently achieve PSI ratings above 1,000, ideal for commercial applications.

When choosing flooring for busy areas, it’s important to check these specifications to make sure it will last and work well under heavy use.

Weight Limits in Flooring

Weight limits are important to make sure that floors can hold the expected loads without risking damage to the structure.

Definition of Weight Limits

Weight limits define the maximum weight that flooring can safely support, which varies by type and construction methods.

For example, aluminum flooring systems can typically support around 200 pounds per square foot because they are lightweight and sturdy, making them a suitable option for elevated installations.

In contrast, calcium sulfate panels offer a weight capacity of approximately 150 pounds per square foot, providing superior sound insulation and fire resistance.

When choosing flooring, think about both the type of material and how much weight it needs to support. Commercial areas might need stronger options, while homes can use lighter materials.

Always check the manufacturer’s guidelines for exact limits.

Common Weight Limits for Different Flooring Types

Common weight limits for flooring materials range significantly, with woodcore panels typically supporting 50-70 lbs/sq ft, while concrete filled steel can handle 200 lbs/sq ft or more.

To better understand your flooring options, consider the following comparisons:

- Hardwood Flooring: Generally supports 40-50 lbs/sq ft, perfect for residential settings with light furniture.

- Vinyl Flooring: Works best in areas with light use, carrying 20-30 lbs per square foot.

- Tile Flooring: Offers about 30-40 lbs/sq ft, ideal for kitchens and bathrooms.

- Concrete Slab: A strong choice, able to hold 150-200 lbs/sq ft, often used in industrial areas.

Assessing these aspects will help you pick the suitable flooring for your requirements.

How to Calculate Weight Limits

Figuring out weight limits involves knowing panel sizes, the materials used, and how loads are spread across the floor system.

To figure out weight limits correctly, begin with these actions:

- Measure the panel’s length, width, and thickness.

- Identify the material’s density.

Use the formula: Weight Limit = (Area x Load Capacity per Square Foot). For example, if a panel is 10 square feet with a load capacity of 50 lbs/sq ft, then the weight limit is 500 lbs.

Online tools like load calculators can simplify this process, allowing for easy changes based on different materials or panel setups.

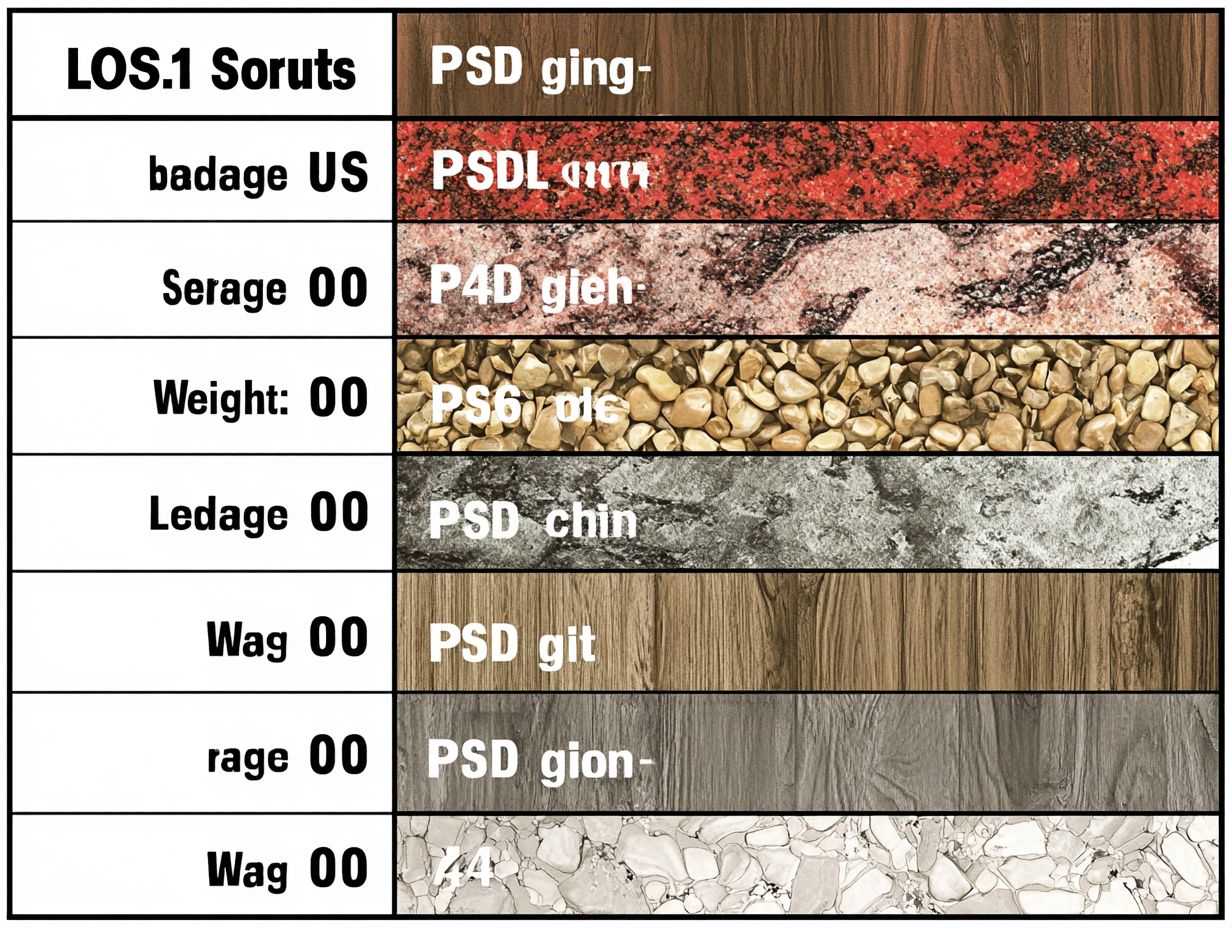

Types of Flooring and Their Load Ratings

Different flooring types have specific weight limits. These limits depend on the materials used and how the flooring is built, affecting where each type can be used.

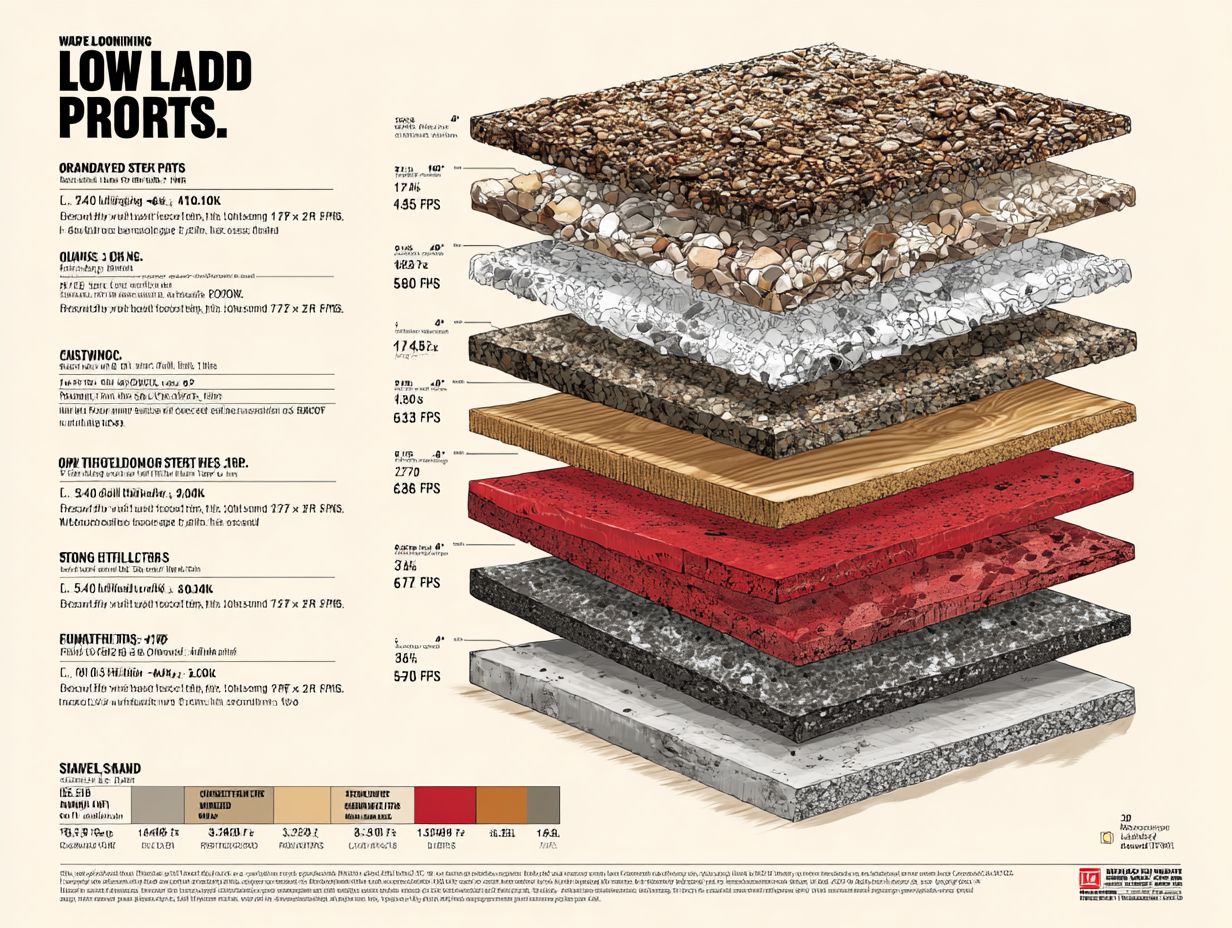

Floor Load Capacity Statistics

Floor Load Capacity Statistics

Warehouse and Residential Floor Load Capacities: Concrete Floor Load Capacity

The Floor Load Capacity Statistics give essential information about how strong concrete floors are, concentrating on live load, dead load, and maximum total load capacities, which are important for planning and safety in both warehouse and residential settings.

Warehouse and Residential Floor Load Capacities detail the strength and limitations of concrete floors, an essential factor in structural engineering. The live load capacity of 40.0 units represents the weight of movable objects, such as furniture and people, that the floor can support. This ability is important for determining how much changing weight a floor can support without damaging it.

- The dead load capacity of 10.0 units accounts for the static weight of the floor itself and any permanent fixtures. Knowing the dead load is important for figuring out the total stress on the structure. This helps confirm that the floor can hold its own weight as well as extra weight.

- The maximum total load for a 10×10 ft area is 4600.0 units. This figure shows the total weight the floor can support, including both moving and stationary loads. It acts as a guide for safe use, making sure that both homes and storage areas can be improved without risking the building’s strength.

These statistics are essential for architects, builders, and engineers to make sure buildings are safe and work well. Knowing these abilities allows experts to create areas that are practical and secure, adjusting to the particular requirements of various places, whether it’s a busy warehouse or a quiet home.

Hardwood Flooring

Hardwood flooring can generally hold up to 50 pounds per square foot, making it suitable for homes and light commercial areas.

This load rating means hardwood is ideal for spaces like living rooms and light traffic areas in retail environments. Factors affecting performance include wood species, moisture content, and installation methods.

For instance, oak and maple have strong load-bearing capacities, while engineered hardwood can handle humidity variations better. In residential contexts, consider using hardwood in dining areas or hallways where foot traffic is moderate.

In commercial settings, pairing hardwood with area rugs can further distribute weight and protect the floor’s integrity.

Laminate Flooring

Laminate flooring generally supports around 40 lbs/sq ft, providing a cost-effective option for areas with moderate foot traffic.

This makes laminate an excellent choice for high-traffic zones such as living rooms and hallways.

In comparison, traditional hardwood may support slightly higher loads but comes with a higher price tag and susceptibility to scratches or water damage.

For instance, in a busy family home, laminate’s durability and ease of cleaning often outperform hardwood. Laminate is ideal in basements where moisture levels might compromise hardwood.

Laminate is affordable, durable, and useful for day-to-day use.

Tile Flooring

Tile flooring can support more than 100 pounds for each square foot, making it ideal for high-traffic areas such as kitchens and bathrooms.

This strength makes tile floors especially useful in places like restaurants or stores, where they need to last a long time.

For instance, a restaurant kitchen, which experiences heavy foot traffic and equipment movement, can rely on ceramic tiles with high load ratings and moisture resistance to withstand spills.

Choosing tiles that are made for wet areas helps keep people safe and makes them last longer. It lowers the chance of slipping and makes cleaning easier. Selecting the right tile improves how a room looks and meets its practical needs.

Carpet and Padding

Carpet and padding together can support around 30 lbs/sq ft, requiring careful consideration for high-weight areas like offices and communal spaces.

To provide proper support in carpeted areas, begin by selecting the correct padding. Choose thick foam or rubber options that spread weight evenly, as these can gradually increase the ability to support loads.

To install, clean the subfloor with a vacuum, make sure it is dry, and cut the padding to fit exactly, leaving no gaps. Choose a thicker carpet for busy areas to make it last longer and prevent early damage.

Regularly rotate furniture to disperse weight evenly, prolonging both the carpet and padding lifespan.

Vinyl Flooring

Vinyl flooring has load ratings like laminate, usually about 40-45 lbs/sq ft, and is more durable and water-resistant.

This makes it ideal for both residential and commercial applications.

For homes, it works well in high-traffic areas like kitchens and hallways, where spills are common. In commercial settings, you’ll find vinyl flooring in retail spaces and healthcare facilities due to its easy maintenance-simply sweeping and mopping usually suffice.

Certain kinds, such as luxury vinyl tiles, can support more weight, which makes them suitable for gyms or places with heavy equipment. Its versatility and low upkeep demands contribute to its widespread popularity.

Regulatory Standards and Guidelines

Following rules and regulations is necessary to make sure flooring is safe and meets requirements in building projects.

Building Codes and Load Ratings

Building rules specify the load limits that flooring must meet to be safe and strong.

For instance, the International Building Code (IBC) specifies load requirements based on occupancy types, which influences flooring material choices.

In residential settings, the typical live load for floors is 40 psf (pounds per square foot), necessitating the use of materials like engineered wood or laminate that can support these loads effectively. Conversely, commercial spaces often require higher load ratings, leading to the use of concrete or natural stone.

Be sure to check local amendments to the IBC, as they may introduce additional parameters that further affect your flooring decisions.

Industry Standards for Flooring Load Ratings

Industry standards, such as those set by ASTM International, provide guidelines for testing and reporting load ratings for various flooring materials.

These standards guarantee that flooring can support certain weights without failing, ensuring safety in homes and businesses.

For example, ASTM E661 describes the test methods for how floor systems react to moving loads, important for wood floors, while ASTM D7032 covers composite floor systems.

Adhering to these standards helps manufacturers produce reliable products, ensuring that laminate flooring (ASTM F1700) or vinyl flooring (ASTM F1913) meet specified performance criteria.

Following rules keeps products safe and helps in selling them.

Practical Applications of Load Ratings

Using load ratings in actual situations confirms that floor choices comply with safety rules and meet performance expectations for particular purposes.

Choosing the Right Flooring for Your Space

Selecting the right flooring involves assessing load capacity needs based on anticipated foot traffic and the weight of furniture or equipment.

Think about these things when deciding:

- Assess the load capacity of different materials, such as hardwood, which typically supports 300 pounds per square foot;

- vinyl, suitable for lighter use; or

- porcelain tiles, which offer great durability under heavy loads.

Next, evaluate material properties; for instance, choose cork for thermal insulation in cooler climates, or opt for bamboo if sustainability is a priority.

Consider environmental conditions like humidity and temperature fluctuations, as these will influence material longevity and maintenance needs.

A thorough assessment of these elements will guide you towards the most suitable flooring option for your space.

Load Testing and Assessment

Load testing is a critical procedure to verify that flooring systems meet specified load ratings and safety standards before installation.

To perform successful load testing, follow these steps:

- First, determine the load requirements specified in local building codes.

- Next, use tools like a load cell or pressure gauge to measure the weight applied to the flooring.

- Organizations such as the American Society for Testing and Materials (ASTM) offer standardized procedures for testing.

- Think about hiring a certified testing service, such as Intertek or UL. They offer expert evaluations and certifications to confirm safety standards are met.

This thorough approach can prevent costly failures post-installation.

Summary of Key Points

Key takeaways include the significance of load ratings, the factors affecting PSI and weight limits, and the importance of compliance with industry standards.

To keep floors safe and lasting, always look at the manufacturer’s load ratings in the technical details.

For example, residential tiles may typically support a PSI of 2,000, whereas commercial options could handle upwards of 5,000 PSI.

When considering weight limits, factor in both the furniture and foot traffic expected. Compliance with standards such as ASTM International can guide you in selecting appropriate materials.

Always consult with professionals or use tools like the National Wood Flooring Association’s guidelines for flooring installation safety.

Frequently Asked Questions

What is a flooring load rating in PSI?

A flooring load rating in PSI (pounds per square inch) is a measurement of the amount of weight a flooring material can support per square inch. This rating is important to consider when selecting flooring for commercial or industrial spaces where heavy objects or high foot traffic may be present.

How are flooring load ratings in PSI determined?

Flooring load ratings in PSI are found through thorough testing in a controlled setting. The materials are tested with force and pressure to find their breaking point. This breaking point is then divided by the total area to calculate the load rating in PSI.

What is the weight limit for flooring with a load rating of 1000 PSI?

The weight limit for flooring with a load rating of 1000 PSI will depend on the total area of the floor. For example, if the flooring has a total area of 100 square feet, the weight limit would be 100,000 pounds (1000 PSI x 100 square feet). It is always important to consult with a professional to determine the appropriate weight limit for a specific flooring material.

What is the difference between a flooring load rating in PSI and a weight limit?

A flooring load rating in PSI is a measurement of the amount of weight a flooring material can support per square inch. A weight limit, on the other hand, is the maximum weight that the flooring can support over its total area. The load rating in PSI is used to determine the weight limit for a specific flooring material.

Why is it important to consider flooring load ratings in PSI when selecting flooring for commercial or industrial spaces?

In areas with lots of movement or heavy items, the flooring needs to hold a specific weight without cracking or getting damaged. By looking at flooring load ratings in PSI, you can make sure the flooring can hold the needed weight and stay strong in these areas.

How can I find out the flooring load rating for a specific type of flooring?

The flooring load rating can usually be found in the product specifications or technical data sheet for the flooring material. If this information is not readily available, you can also contact the manufacturer or a professional flooring installer for more information. You need this information to choose flooring for areas with lots of foot traffic or heavy items.