Hardwood Flooring Finishes – Polyurethane vs Oil vs Wax

Choosing the right wood finish can make all the difference in the aesthetic appearance and durability of your hardwood flooring. In this article, we will look at the three main types of finishes: polyurethane, hardwax oil, and wax. Each option offers unique benefits and film build characteristics, helping you achieve the perfect balance between style and protection. Find the finish that will give your home long-lasting beauty and strength.

Key Takeaways:

Contents

- Hardwood Flooring Finish Preferences

- Polyurethane Finishes

- Oil Finishes

- Wax Finishes

- Comparison of Finishes

- Frequently Asked Questions

- What are the differences between polyurethane, oil, and wax hardwood flooring finishes?

- Which type of hardwood flooring finish is the most durable?

- Are there any environmental concerns with using polyurethane, oil, or wax finishes on hardwood flooring?

- How do I know which hardwood flooring finish is best for my home?

- Can I change the finish on my hardwood floors if I want to switch from polyurethane to oil or wax?

- Do polyurethane, oil, and wax finishes require different methods of cleaning and maintenance?

Importance of Choosing the Right Finish

The right wood finish makes the wood look better and protects it from damage, moisture, and outside elements.

Picking a finish like polyurethane can greatly increase durability. For example, water-based polyurethane resists moisture well and dries in just two hours, which is perfect for kitchens and bathrooms.

In contrast, oil-based finishes provide superior wear protection but take longer to cure, which can be inconvenient. A study by the National Wood Flooring Association found that finishes with at least a 50% solids content tend to resist scratches and dents better, prolonging the lifespan of your wood surfaces.

Always consider the specific environment and usage when selecting the right finish. For a comprehensive understanding of different hardwood types and their characteristics, check out our Complete Guide to Hardwood Flooring Types and Species.

Overview of Common Finishes

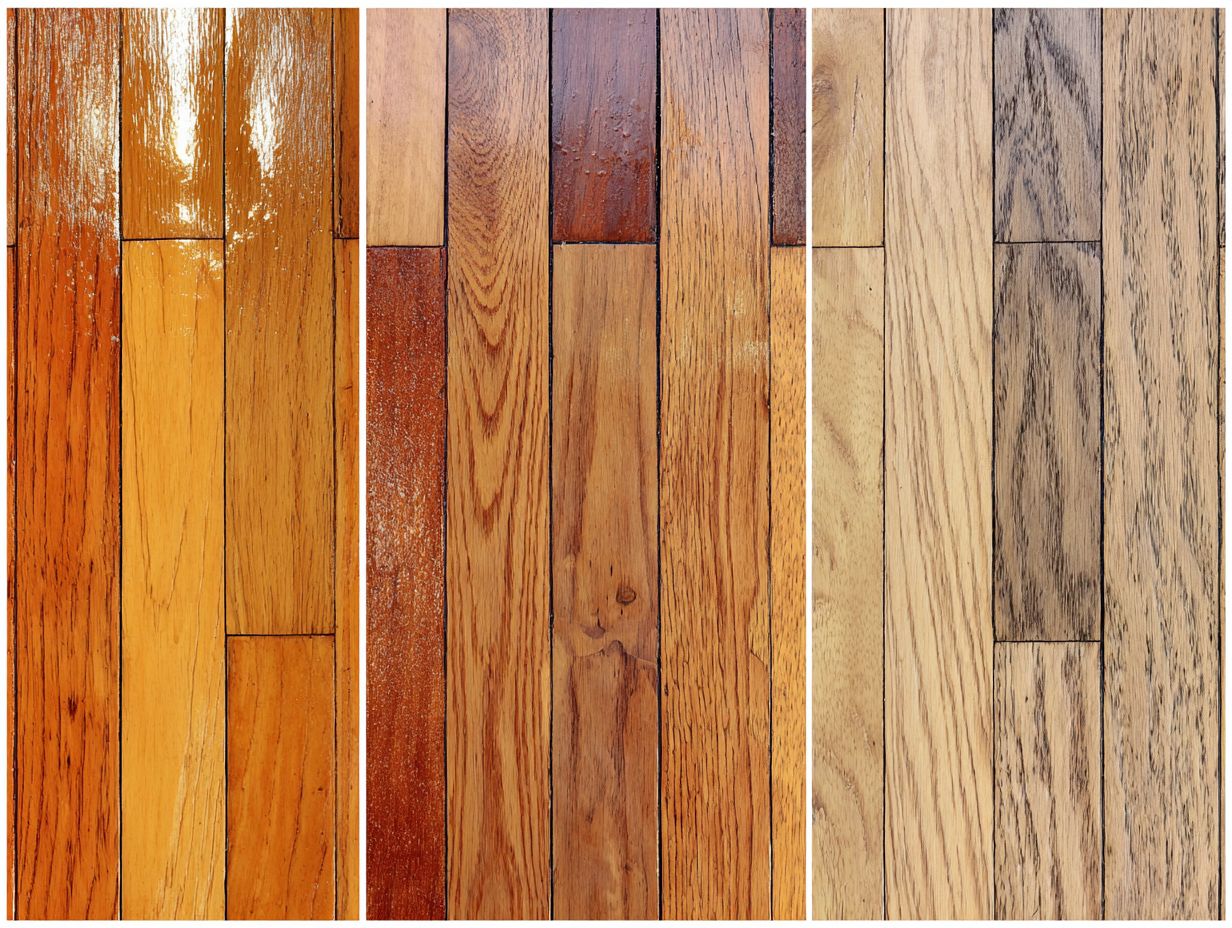

Hardwood floors can be finished with various products, including polyurethane, oil, and wax, each offering distinct benefits and drawbacks.

Polyurethane is durable and water-resistant, making it ideal for high-traffic areas. That’s why many families choose it for their homes.

Oil finishes, while requiring more frequent reapplication, offer a natural look and feel, enhancing the wood’s grain and color.

Wax finishes give a warm, traditional appearance but demand consistent maintenance and are less moisture-resistant.

For long-term use, consider polyurethane or oil, while wax is best suited for less-used spaces like bedrooms.

Assess your lifestyle and desired aesthetics to choose the right finish for your hardwood floors.

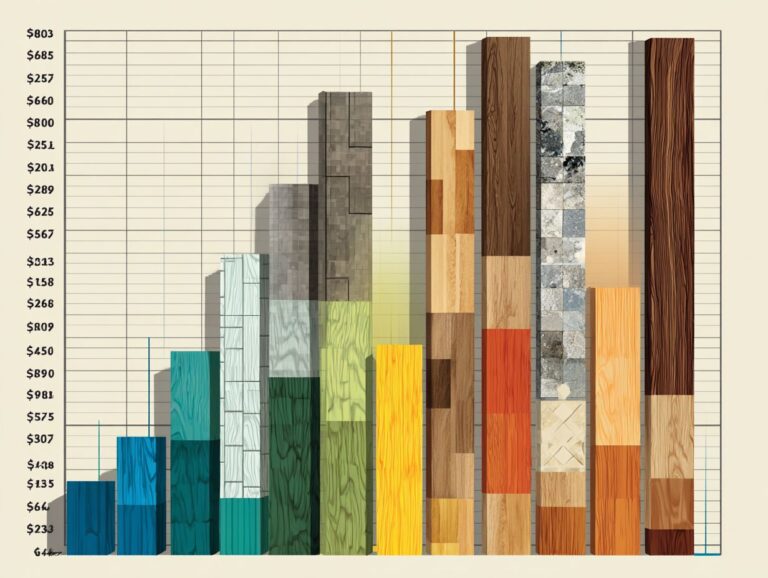

Hardwood Flooring Finish Preferences

Hardwood Flooring Finish Preferences

Finish Types and Preferences: Finish Appearance Preferences

The data on Hardwood Flooring Finish Preferences gives information about what consumers like regarding the shine levels of hardwood floor finishes. Knowing these preferences can help manufacturers and retailers adjust their products to meet customer needs and match their marketing plans.

Finish Types and Preferences Research indicates that people have clear preferences regarding how hardwood floors look. The data indicates a clear inclination towards varying gloss levels:

- Low Matte Gloss Level: Preferred by 10% of consumers, this finish offers a subtle, understated look. People often pick it because it covers up flaws and scratches, which makes it useful in busy areas or in houses with pets and kids.

- Standard Matte Gloss Level: Attracting 20% of the market preference, this finish strikes a balance between aesthetics and practicality. It gives a gentle shine that brings out the wood’s natural beauty and keeps a more laid-back look compared to high gloss finishes.

- Semi-Gloss Level: Leading the preference chart with 40% This finish is popular for its shiny appearance, which makes the wood grain stand out and adds a bit of style to a room. It is often selected for formal spaces where a more polished look is desirable.

The prominence of the Semi-Gloss Level, accounting for the highest percentage, suggests a consumer trend towards finishes that combine aesthetic appeal with functional benefits. This preference for a shinier finish could also be driven by trends in interior design that emphasize brightness and reflectivity, enhancing the perception of space.

Knowing these preferences helps in making choices for product creation and marketing. By concentrating on finishes that match what customers want, companies can adjust their product lines to attract more buyers. Retailers can also help customers by explaining the benefits and best uses of each gloss level, improving customer satisfaction and loyalty.

Polyurethane Finishes

Polyurethane finishes are widely used because they are strong and offer good protection. They are especially beneficial when used in conjunction with different hardwood flooring options.

They are a common choice for professionals and DIYers. See also: Complete Guide to Hardwood Flooring Types and Species.

What is Polyurethane?

Polyurethane is a synthetic varnish that forms a protective film on the surface of wood, enhancing its durability and aesthetic appeal.

It consists of a mixture of polymers and can be water-based or oil-based, each offering distinct benefits. Water-based polyurethane dries fast, which makes it perfect for projects that need to be finished quickly.

On the other hand, oil-based options provide a richer finish and greater durability but take longer to cure.

When applying, prepare the wood by sanding it to create a smooth surface, then use a high-quality brush or roller for an even coat. Typically, two to three coats are recommended for optimal protection against scratches and moisture.

Types of Polyurethane Finishes

Polyurethane finishes come in water-based and oil-based variants, each offering unique advantages in terms of application and finish appearance.

Water-based polyurethane dries quickly, usually within 2-3 hours, making it ideal for projects that require a fast finish. It has lower VOC (volatile organic compound) levels, meaning less odor and a more environmentally friendly option.

On the other hand, oil-based polyurethane takes up to 8 hours to dry, giving the wood a deeper, amber color that gets better over time, improving the wood’s natural look.

When choosing, consider your project timeline and aesthetic preference: if speed and a clear finish are priorities, opt for water-based; for a warmer, classic look, go for oil-based.

Advantages of Polyurethane Finishes

Polyurethane finishes are known for their high durability, excellent chemical resistance, and ability to maintain a natural wood look.

To achieve the best results, consider using water-based polyurethane for indoor furniture, as it dries faster and emits fewer fumes.

On the other hand, oil-based polyurethane, which takes longer to dry, tends to provide a richer tone and is ideal for high-traffic areas.

For use, a good synthetic brush helps stop bubbles and streaks, while a foam roller can quickly cover bigger areas.

Always work in a well-ventilated area, applying thin layers to avoid runs and ensuring an even finish.

Disadvantages of Polyurethane Finishes

Despite their many benefits, polyurethane finishes can pose challenges, including difficulty in repair and a potentially higher maintenance frequency.

One significant issue is localized repair; matching the sheen and color can be tricky. To address this, keep an extra can of the same finish on hand for touch-ups.

Limitations in color options can be resolved by selecting products with added pigments or by custom mixing at your local supplier.

While surface scratches can occur, applying a minor repair kit-like a blend of acrylic paint and varnish-can effectively conceal blemishes. Regular maintenance with appropriate cleaners will also prolong the finish’s lifespan.

Application Process for Polyurethane

For the best outcome, prepare the surface well and follow a planned method when applying polyurethane.

- Start by sanding the surface with 220-grit sandpaper to remove imperfections and promote adhesion.

- Clean the dust thoroughly with a vacuum or damp cloth.

- Once dry, use a foam brush or roller to apply the first coat of polyurethane, ensuring a thin, even layer.

- Allow it to dry for at least 4-6 hours, then lightly sand again before adding the second coat.

- A third coat is recommended for high-traffic areas.

- Keep windows open and use fans to help dry and reduce smell.

Maintenance and Longevity

Regular maintenance is key to preserving the longevity of polyurethane finishes, ensuring they continue to protect your investment effectively.

To maintain these finishes, clean surfaces monthly using a pH-neutral cleaner to avoid damage.

Check often for marks or scratches; quickly smooth them out with fine sandpaper and apply a thin coat of polyurethane if needed.

Avoid placing heavy furniture directly on the surface, as it can cause dents.

To maintain its appearance and durability, apply a fresh coat of polyurethane every 3-5 years, especially in areas with high foot traffic.

Oil Finishes

Oil finishes improve the look of wood and provide a protective layer that is easy to maintain. For an extensive analysis of wood treatment options, our Complete Guide to Hardwood Flooring Types and Species examines the best practices for enhancing and preserving the beauty of your floors.

What is Oil Finish?

An oil finish penetrates the wood surface, providing a protective barrier without forming a synthetic layer on top.

This method improves the natural look of the wood, showing grain patterns and allowing the finish to breathe. Popular options include tung oil, which offers a durable, water-resistant finish, and linseed oil, known for its ease of application.

To apply, simply wipe the oil onto the wood with a clean cloth, allowing it to soak in for 15-30 minutes, then wipe away the excess. For the best results, multiple coats are recommended, with light sanding between applications to improve adhesion and smoothness.

Types of Oil Finishes

Common types of oil finishes include linseed oil, hardwax oil, and natural oils, each with specific properties and applications.

Linseed oil, for example, dries relatively slowly but provides a deep, rich finish ideal for walnut or oak surfaces. Indoor furniture should have very low VOC levels, ensuring it is safe for use at home.

In contrast, hardwax oil dries faster, offering a durable finish suitable for high-traffic areas like kitchen countertops. Its formulation combines oil and wax, enabling easy maintenance.

Natural oils, often derived from plant sources, give a subtle sheen and are best for pieces that need frequent upkeep. Choosing the right oil depends on the desired aesthetic and usage of the wood.

Advantages of Oil Finishes

Oil finishes are praised for their low maintenance requirements and ability to maintain a natural wood appearance.

These finishes provide important advantages.

- First, they are easy to apply, often requiring only a cloth and a few dedicated hours.

- Second, they allow for localized repairability; if a section gets damaged, you can simply add more oil to that area without needing to refinish the entire piece.

Oil finishes usually don’t contain harmful substances, so they are safer to use indoors. People often say that reapplying the product every few years keeps their wood surfaces looking fresh and new.

Disadvantages of Oil Finishes

Oil finishes offer many advantages, but they also have downsides, such as needing regular upkeep and being less hard-wearing than synthetic choices.

A major downside is that they can scratch easily, which makes them a poor choice for places with heavy foot traffic. Oil finishes have less protection against chemicals, so spills can cause more damage if not quickly cleaned up.

To fix these issues, remember to put on a new coat of finish every six months to a year to maintain its protection. Following this routine helps wooden surfaces keep their good looks and reduces the chance of damage as time goes by.

Application Process for Oil Finishes

Putting on an oil finish is easy and doesn’t need many tools or much prep work.

- Start by selecting the right oil; options include tung oil for durability or linseed oil for a traditional finish.

- Prepare the surface by sanding it to a smooth finish and removing all dust.

- Using a clean rag or a brush, apply a thin, even coat of oil, working in the direction of the wood grain.

- Allow it to soak in for about 15-30 minutes before wiping away any excess.

- For best results, put on at least two to three layers, letting them dry for 24 hours between applications for a deep, smooth finish.

Maintenance and Longevity

Maintenance for oil finishes primarily involves regular cleaning and reapplication to maintain their protective qualities.

To maintain the oil finish and protect surfaces, clean them with a damp cloth every few weeks and avoid using harsh cleaners.

Reapply oil finishes every 6-12 months, depending on their use and exposure to weather. For reapplication, lightly sand the surface with fine-grit paper to promote adhesion before applying a thin coat of oil, such as tung or Danish oil.

This method keeps surfaces looking attractive and increases their strength, ensuring they remain fresh and tidy.

Wax Finishes

Wax finishes give wood a deep, cozy look and come with specific upkeep needs.

What is Wax Finish?

Wax finishes consist of natural or synthetic waxes that form a subtle protective layer over the wood surface.

These finishes improve wood’s appearance by adding a gentle shine and highlighting its natural grain.

For instance, beeswax can provide a warm, organic finish, ensuring easy application with just a soft cloth. Synthetic waxes, like carnauba, offer a more durable, water-resistant surface, ideal for high-traffic areas.

To achieve the best results, sand the wood lightly before application and apply multiple thin coats, allowing each to dry thoroughly. Putting on wax every few months will help the wood stay shiny and protected.

Advantages of Wax Finishes

Wax finishes are easy to apply and maintain, providing a unique aesthetic appeal while allowing for simple repairs.

To achieve the best results with wax finishes, start by preparing your wood surface with sanding, ensuring a smooth base.

Next, apply a thin layer of wax using a soft cloth or applicator, working in the direction of the wood grain.

Popular wax options include:

- Clear Johnson’s Paste Wax for its durability

- Osmo Polyx-Oil for added moisture resistance

After the initial application, buff the surface with a clean cloth for a natural shine.

Routine maintenance involves applying a fresh coat of wax every few months, depending on usage and wear, keeping the finish functional and appealing.

Disadvantages of Wax Finishes

Wax finishes can be less durable and require more frequent maintenance compared to other finishing options.

Because of their vulnerability to scratches and stains, wax finishes may not be ideal for high-traffic areas. You should reapply them every few months to maintain their appearance.

To make wood last longer, combine wax with an acrylic or polyurethane coating. This will shield the wood underneath and keep the wax’s shine on the surface.

Using soft cleaning cloths and avoiding harsh chemicals will help preserve the finish longer, reducing the frequency of maintenance.

Application Process for Wax Finishes

The application of wax finishes is a simple process that can be performed with minimal tools and technique.

Begin by getting the surface ready: make sure it’s clean and completely dry. Use a clean cloth or applicator pad, applying the wax in a thin, even layer using circular motions.

Allow the wax to set for 10-15 minutes, enabling it to bond effectively. After setting, buff the surface with a soft cloth to achieve a high shine.

For best results, consider using:

- Carnauba wax for durability

- Beeswax for a more natural finish

Wipe and care for the surface regularly, every few months, to keep it looking fresh.

Maintenance and Longevity

To maintain the beauty of wax finishes, regular upkeep is essential, requiring specific maintenance procedures.

Start by dusting surfaces with a microfiber cloth to prevent scratches. Every 3-6 months, use a special wax cleaner to remove dirt and grime without damaging the surface.

When reapplying wax, choose a high-quality product like Minwax Paste Finishing Wax. Aim for a thin layer, allowing it to cure for 10-15 minutes before buffing with a soft cloth.

This method improves shine and makes the finish last longer, keeping your furniture looking great for years.

Comparison of Finishes

Looking at the different finishes is important to see if they work well in specific situations and places.

Durability

Durability varies significantly across finishes, influencing both their performance over time and required maintenance frequency.

Polyurethane finishes are recognized for their strong wear resistance, which makes them suitable for busy spaces like kitchens and hallways. However, they take more time to dry.

Oil finishes go into the wood, give a natural look, and are simple to apply, but they need to be reapplied each year.

Wax finishes don’t last long, so they are good for furniture that isn’t used much. They have a soft glow but require maintenance every few months.

Picking the right finish is important depending on the needs of your project.

Frequently Asked Questions

What are the differences between polyurethane, oil, and wax hardwood flooring finishes?

Polyurethane is a synthetic finish that creates a hard, durable surface on hardwood floors. Oil finishes penetrate the wood to provide a natural, matte look, while wax creates a softer, matte finish on the surface of the wood.

Which type of hardwood flooring finish is the most durable?

Polyurethane is typically the most durable option, as it creates a strong barrier against scratches, stains, and water damage. Regular upkeep and reapplication can make oil and wax finishes last longer.

Are there any environmental concerns with using polyurethane, oil, or wax finishes on hardwood flooring?

Polyurethane finishes may emit volatile organic compounds (VOCs) during the drying process, which can have negative effects on indoor air quality. Oil and wax finishes are generally considered more environmentally friendly, as they are made from natural materials and have low VOC emissions.

How do I know which hardwood flooring finish is best for my home?

The best finish for your hardwood floors depends on your personal preferences and lifestyle. If you have children or pets, a polyurethane finish may be the best choice for its durability. If you prefer a more natural look and are willing to do regular maintenance, oil or wax finishes may be a better fit.

Can I change the finish on my hardwood floors if I want to switch from polyurethane to oil or wax?

Yes, it is possible to change the finish on hardwood floors, but it can be a labor-intensive process. Stripping and sanding the old finish off the floors is necessary before applying a new finish. It’s best to consult with a professional before attempting this process.

Do polyurethane, oil, and wax finishes require different methods of cleaning and maintenance?

Yes, each type of finish has its own specific cleaning requirements. Polyurethane finishes can be cleaned with a mild soap and water solution, while oil and wax finishes require special products for maintenance. It’s important to follow the manufacturer’s instructions for the best results.