Laminate Click Lock Systems – Types and Installation

Looking for a flooring solution that combines the beauty of traditional flooring with the convenience of modern technology? Laminate click lock systems provide flooring choices that are both stylish and easy for homeowners to install themselves. Whether you’re looking at luxury vinyl tile or other materials, this guide will cover different types, advantages, and installation tips, helping you decide what works best for your home project.

Key Takeaways:

Contents

- Types of Laminate Click Lock Systems

- Materials Used in Laminate Click Lock Systems

- Installation Process for Laminate Click Lock Systems

- Maintenance and Care for Laminate Click Lock Floors

- Laminate Flooring Market Data

- FAQs

- Frequently Asked Questions

- What are the different types of laminate click lock systems?

- What are the advantages of using a laminate click lock system?

- Can I install laminate click lock flooring over existing flooring?

- Do I need any special tools for installing laminate click lock flooring?

- How do I maintain and clean laminate click lock flooring?

- Can laminate click lock flooring be installed in high moisture areas?

What are Laminate Click Lock Systems?

Laminate click lock systems are flooring options designed with edges that fit together, enabling fast installation without glue or nails.

This new design is different from usual flooring in many aspects. While traditional flooring often requires adhesive or nails for stability, click lock systems snap together easily, significantly reducing installation time-often to a matter of hours rather than days.

The ease of removal makes them ideal for renters or those wanting flexibility in their space. Brands like Pergo and Quick-Step offer a variety of styles, ensuring aesthetic appeal while maintaining durability.

This convenience combined with attractive designs makes laminate click lock systems a preferred choice for modern homeowners.

Benefits of Using Click Lock Systems

Click lock systems cut down the time and expense needed for installation, which is why they are favored by both do-it-yourself fans and professional installers.

These systems offer several advantages.

- First, they require no adhesive, allowing for a cleaner installation process.

- They also install up to 30% faster than traditional glue-down methods, saving both time and labor costs.

- Their increased durability makes them well-suited for high-traffic areas, while their moisture resistance helps prevent warping in humid conditions.

- Eco-friendly options are available, appealing to environmentally conscious consumers.

- Homeowners can expect to save approximately 20% on installation costs compared to traditional flooring solutions.

Types of Laminate Click Lock Systems

Knowing the various kinds of laminate click lock systems helps buyers select the right choice for their installation needs.

Standard Click Lock Systems

Standard click lock systems have an easy-to-use locking mechanism that works well for homes and easy setups.

These systems need only basic tools, like a tapping block and a pull bar, which makes DIY installation easy to do. They work well in areas with moderate foot traffic, such as living rooms or bedrooms.

Pergo TimberCraft is usually chosen and is priced at approximately $2.50 per square foot. Offering scratch and water resistance, it’s perfect for families and pets.

To install, follow these steps:

- Start in a corner.

- Lay down the first plank.

- Align subsequent planks at a 20-degree angle to engage the lock, tapping gently until secure.

Angle/Angle Click Lock Systems

Angle/angle click lock systems are designed for installations that require a more secure fit, particularly in spaces with irregular layouts.

These systems use a special locking system that keeps connections secure even in difficult places, such as attics or basements.

To install, you’ll need a miter saw for accurate cuts and a rubber mallet to fit the pieces without causing damage.

For example, a contractor reported using this system to achieve flawless fittings in a custom kitchen remodel, reducing air gaps and improving thermal efficiency. Using these locks has been useful for projects that need more strength, especially in busy areas.

Drop Lock Systems

Drop lock systems offer a unique method of installation that allows for rapid placement of planks, often completing a room in under an hour.

These systems are simple to install and suitable for those with no prior experience, as they don’t need glue or nails.

For instance, you can use brands like Pergo or Mohawk, which average around $2 to $5 per square foot.

Their connecting system guarantees a tight fit, usually resulting in fewer gaps than older techniques. This speeds up the installation process and reduces the risk of moisture damage, which is important for humid areas.

Drop lock systems are simple to operate and durable, which is why homeowners often choose them.

Glue-less Click Lock Systems

Click lock systems don’t need glue and resist moisture well, making them suitable for damp areas.

These systems work by using interlocking edges that securely fit together, providing a watertight seal without compromising appearance.

The Pergo Outlast range is designed to last longer with its waterproof surface, making it a good choice for bathrooms or basements.

To install, make sure the subfloor is clean and even. Align the planks and click them together, leaving space for expansion around the edges.

This method reduces installation time and eliminates the mess associated with traditional bonding agents.

Materials Used in Laminate Click Lock Systems

The materials used in laminate click lock systems influence how long they last, how they look, and how well they work in different settings.

High-Pressure Laminate (HPL)

High-pressure laminate (HPL) is a durable, moisture-resistant material that provides an attractive finish suitable for both residential and commercial use.

HPL is favored in laminate click lock systems for its superior strength, aesthetic versatility, and affordability.

For example, it resists scratches and stains better than wood or particle board, making it a good choice for places with lots of activity.

Cost-wise, HPL typically ranges from $1.50 to $3.00 per square foot, compared to $2.00 to $5.00 for solid wood and $1.00 to $2.50 for lower-grade laminates.

Its easy installation also means lower labor costs, which is another strong reason for its wide use in flooring and cabinetry.

Direct Pressure Laminate (DPL)

Direct pressure laminate (DPL) is a cost-effective option that offers reliable performance and various design choices, making it a favorite for budget-conscious buyers.

DPL typically costs between $1.50 and $3.00 per square foot, significantly less than high-pressure laminate (HPL), which ranges from $3.00 to $6.00.

While DPL is suitable for residential applications like kitchen countertops and bathroom vanities, it may not withstand heavy use as well as HPL.

Homeowners should consider the intended use; for example, if the surface will frequently experience scratches or heat, HPL is the better option despite the higher cost. DPL works effectively in places with less traffic and comes in a variety of stylish finishes.

Wood Fiber Core vs. High Density Fiberboard (HDF)

Choosing between wood fiber core and high-density fiberboard (HDF) impacts the flooring’s longevity, sound insulation, and comfort underfoot.

Wood fiber core is excellent at absorbing sound, which makes it perfect for buildings with multiple floors or units where reducing noise is very important.

In contrast, HDF is more durable and resists damage well, making it suitable for high-traffic areas such as hallways and living rooms.

When installing, consider the moisture levels in your space; wood fiber can expand in humid conditions, whereas HDF tends to perform consistently.

Choosing the best option will depend on your exact requirements for comfort, how it looks, and how easy it is to take care of.

Installation Process for Laminate Click Lock Systems

Correct installation is essential for getting the most out of the lifespan and function of laminate click lock systems, while providing a smooth appearance and texture.

Preparation of the Subfloor

A well-prepared subfloor is essential for the success of the installation, as it directly affects the stability of the laminate flooring.

Begin by checking for moisture using a moisture meter; readings should be below 12%. Next, thoroughly clean the surface to remove debris and dust that could interfere with adhesion.

If the subfloor is uneven, use a self-leveling compound, applying it according to manufacturer instructions.

Tools you’ll need include:

- Moisture meter

- Vacuum

- Trowel

- Possibly a floor scraper

This preparatory work usually takes 2-4 hours, ensuring a solid foundation for your laminate flooring to prevent issues like buckling or gaps.

Acclimatization of Laminate Planks

Acclimatization of laminate planks is a critical step that prevents warping and buckling after installation, ensuring long-term performance.

To acclimatize laminate planks, allow them to sit in the room where they will be installed for 48 to 72 hours. Keep the temperature between 60 degreesF and 80 degreesF, and humidity between 30% and 50%.

Avoid placing planks directly on cold or hot surfaces, as that can lead to uneven acclimatization.

A common mistake is rushing this step; cutting the acclimatization period in half can lead to significant problems like expansion gaps or buckling.

Checking moisture levels with a meter can also guide your decision on whether acclimatization is sufficient.

Tools Required for Installation

Having the right tools available can make installing laminate click lock systems faster and easier.

Essential tools include:

- a tapping block ($10)

- pull bar ($15)

- a quality circular saw ($100-$300)

Choose a tapping block that fits snugly over the planks to prevent damage while using it. A pull bar should have a broad edge, which helps in joining the boards more easily.

For straight cuts, purchase a laser level (around $30) to keep your work lined up. These tools will help you finish your laminate flooring project quickly and like a pro.

Step-by-Step Installation Guide

Following a step-by-step guide when installing laminate click lock flooring prevents errors and makes sure it is done properly.

- Start by preparing your subfloor; it should be clean, dry, and level.

- Next, gather tools like a measuring tape, saw, and spacers.

- Start by measuring the room to figure out the plank arrangement. Make sure to stagger the joints for strength.

- After planning the layout, put down the base layer and seal the joints.

- Then, start placing the planks, clicking them together, and using spacers to maintain expansion gaps.

- This process typically takes about 4-6 hours, depending on room size.

- Finish by installing baseboards to complete the look.

Common Mistakes to Avoid

Avoiding common installation mistakes can save time, money, and frustration, ensuring your laminate flooring performs as expected.

Here are five common mistakes during laminate flooring installation and how to rectify them:

- Improper Acclimation: Failing to acclimate the flooring can cause expansion or contraction. Keep the laminate in the installation area for at least 48 hours.

- Not Using a Vapor Barrier: Skipping this step can lead to moisture damage. Always install a vapor barrier to protect against moisture from the subfloor.

- Incorrect Spacing: Forgetting to leave expansion gaps around walls can create buckling. Aim for a -inch gap to allow movement.

- Uneven Subfloor: An uneven base can cause squeaks and gaps. Apply a leveling compound to create an even surface before installation.

- Ignoring Manufacturer’s Instructions: Always refer to the specific guidelines provided. Each laminate brand may have specific steps needed to keep the warranty valid.

Maintenance and Care for Laminate Click Lock Floors

Taking care of your laminate click lock floors regularly helps them stay in good condition and last longer, making them a great part of your home.

Cleaning Tips

A proper cleaning regimen using the right products can extend the life of laminate click lock flooring while maintaining its appearance.

To clean your laminate flooring effectively, use a pH-neutral cleaner like Bona or Murphy Oil Soap, which are safe for laminate surfaces.

Sweep or vacuum regularly to remove dirt and debris, and mop weekly with a damp microfiber mop to avoid excess water damage.

For stubborn stains, mix equal parts vinegar and water, but avoid scrubbing with abrasive materials.

Establish a cleaning schedule:

- Daily sweeping

- Weekly mopping

- Monthly deeper cleanings

to keep your flooring in great shape.

Repairing Damaged Planks

Knowing how to repair damaged laminate planks can save you from costly replacements and maintain the integrity of your flooring.

To tackle scratches, begin with a laminate repair kit, which typically includes markers or wax sticks matching your floor color.

For deeper scratches or chips, sand the area lightly before applying the repair solution. Use a putty knife to fill in gaps with a color-matched epoxy filler, ensuring it levels with the surrounding surface. After it dries, sand it down for a smooth finish.

Tools you’ll need include:

- Fine-grit sandpaper

- A putty knife

- The repair kit itself, available at home improvement stores.

Final Thoughts on Laminate Click Lock Systems

Choosing laminate click lock systems improves the look of your home and uses materials that are better for the environment.

To make the most of your laminate flooring investment, consider factors such as installation ease, water resistance, and durability.

For example, brands like Pergo offer products that resist scratches well, perfect for active households. AquaGuard provides waterproof choices suitable for kitchens and bathrooms.

Tools such as a tapping block and pull bar can facilitate the installation process, ensuring a tight fit without damaging the planks.

Figure out what you need in terms of use and appearance to choose a laminate floor that combines style with practicality.

Laminate Flooring Market Data

Laminate Flooring Market Data

Market Overview: Market Size and Forecast

Market Overview: Growth Rates

Market Segmentation: Laminate Flooring Types

Market Segmentation: Application

The Laminate Flooring Market Data gives a detailed look at the market’s size right now, expected growth, and breakdown by type and use. This data provides important information about the trends affecting the laminate flooring industry.

Market Overview begins with the market size and forecast, indicating significant fluctuations. The market value was $57.65 billion in 2021, decreased to $33.95 billion in 2024, and is projected to grow dramatically to $101.31 billion by 2030 before declining again to $52.1 billion by 2032. These shifts highlight the market’s volatility and potential for growth, driven by factors like economic conditions, construction industry trends, and consumer preferences.

The compound annual growth rate (CAGR) reinforces these trends, with a 5.8% CAGR from 2021 to 2030 and a 5.5% CAGR from 2025 to 2032. These growth rates suggest a steady increase in demand for laminate flooring, driven by its affordability, durability, and aesthetic appeal.

Market Segmentation data examines the kinds and uses of laminate flooring. High-Density Fiberboard (HDF) dominates with 50% of the market share, followed by Medium-Density Fiberboard (MDF) at 30%. The widespread use of HDF shows that it is long-lasting and withstands moisture well, making it popular with buyers.

In terms of application, the residential sector leads with 45%, reflecting homeowners’ preference for cost-effective and easy-to-maintain flooring solutions. The commercial sector follows at 35% where strength and ability to change designs are important. The industrial sector accounts for 20%, highlighting how laminate flooring works well in various settings.

Overall, the Laminate Flooring Market Data shows a complicated situation influenced by different factors. Although market ups and downs can be difficult, there are still chances for growth due to new technology and changing consumer demands. Knowing these trends allows people in the laminate flooring business to make smart decisions and enjoy the newest developments in the industry.

FAQs

Answering frequent questions about laminate click lock systems can help clear up confusion and aid people in deciding whether to buy them.

How long do laminate click lock floors last?

Laminate click lock floors typically last between 15-25 years, depending on maintenance, quality of materials, and daily wear and tear.

To extend the life of your laminate flooring, follow a few essential maintenance tips.

Start by regularly sweeping or vacuuming to remove dirt and debris, which can scratch the surface. Use a damp mop with a manufacturer-recommended cleaner for deeper cleans, avoiding excess water that can seep into seams.

Consider placing felt pads under furniture legs to prevent indentations.

For warranty concerns, select better quality choices that frequently offer extended coverage-such as 30 years or longer-giving you confidence in your investment.

Frequently Asked Questions

What are the different types of laminate click lock systems?

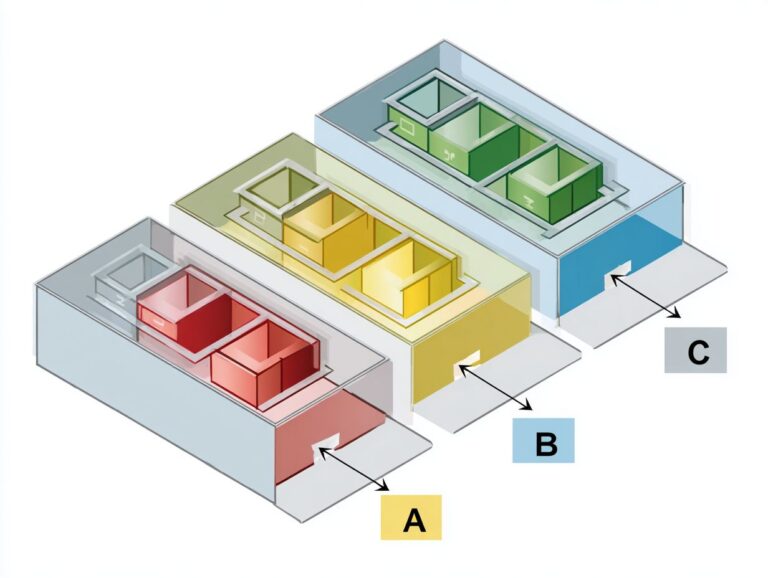

There are three main types of laminate click lock systems: interlocking, drop and lock, and angle-angle. Interlocking systems have a tongue and groove design, while drop and lock systems have a drop and lock mechanism. Angle-angle systems have a locking mechanism on both the long and short edges of the plank.

What are the advantages of using a laminate click lock system?

Laminate click lock systems are easy to install, require no glue or nails, and can be easily removed and reused. They are also more durable and resistant to moisture compared to traditional laminate flooring.

Can I install laminate click lock flooring over existing flooring?

Yes, you can install laminate click lock flooring over existing flooring, as long as the existing flooring is in good condition and level. It is recommended to remove any carpet or padding and to thoroughly clean the surface before installation.

Do I need any special tools for installing laminate click lock flooring?

No, you do not need any special tools for installing laminate click lock flooring. It’s suggested to use a saw, tapping block, and pull bar to simplify the installation process.

How do I maintain and clean laminate click lock flooring?

To maintain and clean laminate click lock flooring, use a damp mop or cloth with a mild cleaner. Avoid using excessive water and harsh chemicals, as this can damage the flooring. It is also important to wipe up any spills or stains immediately to prevent damage to the flooring.

Can laminate click lock flooring be installed in high moisture areas?

Yes, laminate click lock flooring can be installed in high moisture areas, such as bathrooms or kitchens. Make sure to use a moisture barrier beneath the flooring and seal all edges and transitions properly to avoid water damage.