Concrete Flooring – Polished, Stained and Stamped Options

Contents

Introduction to Concrete Flooring

Key Takeaways:

Overview of Concrete Flooring

Concrete flooring comes in various types, such as traditional concrete, polished concrete, stained concrete, and decorative finishes, making it suitable for different purposes.

Traditional concrete offers a strong foundation for industrial areas, while polished concrete results in a shiny surface that improves both the look and long-lasting strength.

Stained concrete offers color options, allowing customization to match dcor. Recent innovations, like self-leveling compounds and translucent concrete, have expanded design possibilities, enabling seamless transitions and unique lighting effects.

For instance, using a self-leveling overlay can turn an uneven floor into a modern, sleek surface in just a day. These upgrades improve the appearance and increase the strength of the floor.

Concrete Flooring Market Overview

Concrete Flooring Market Overview

Market Statistics: Market Growth

The Concrete Flooring Market Overview provides important information about market trends, such as expected growth rates and the market shares of different regions. This data gives a full view of the industry’s direction, showing key opportunities for people involved in the concrete flooring sector.

Market Growth: The global concrete floor coatings market size is anticipated to expand from $2.03 billion USD in 2024 to $3.29 billion USD by 2032, reflecting a steady demand increase. Similarly, the broader concrete flooring market is projected to grow from $47,769.4 million USD in 2025 to $69,962.2 million USD by 2032. These numbers show strong growth, fueled by increasing construction work and the need for long-lasting, easy-to-care-for flooring options.

- The Concrete Floor Coatings Market is expected to experience a 6.2% CAGR from 2025 to 2032, highlighting opportunities in industries prioritizing aesthetics and surface protection. Concurrently, the Industrial Concrete Flooring Market boasts a 5.6% CAGR over the same period, underscoring the importance of durability and cost-effectiveness in industrial applications.

Regional Market Share: The Asia-Pacific region holds a substantial market share, accounting for 44.6% in 2024. This dominance is due to rapid urbanization, infrastructure development, and economic growth. Meanwhile, Europe is noted for the fastest CAGR of 19.2% from 2025 to 2032, driven by technological advancements and an increasing emphasis on sustainable building practices.

The Concrete Flooring Market Overview shows there is a lot of room for growth in both coatings and industrial areas. Regional variations, with Asia-Pacific leading in market share and Europe demonstrating rapid growth, highlight diverse opportunities and challenges. Stakeholders should prioritize innovation, sustainability, and strategic regional expansion to capitalize on these trends. As the industry changes, adjusting to shifts in consumer choices and rules will be important for staying ahead and finding new market opportunities.

Benefits of Concrete Flooring

Concrete flooring is cost-effective, easy to care for, and durable, making it a great option for both homes and businesses.

Concrete floors offer extra energy savings. They reflect light, which lessens the need for more lighting, and help keep areas cooler during summer.

A properly sealed concrete floor can stop moisture issues, which makes it a good option for areas where spills or dampness often occur. For homeowners planning to install concrete flooring, using tools like a concrete mixer for small batches or hiring a professional for larger jobs can make the process smooth and effective.

Think about including decorative finishes to give your space a unique touch while keeping the benefits of strong materials.

Polished Concrete Flooring

Polished concrete floors are popular in modern design because they have a shiny, smooth look and are long-lasting.

What is Polished Concrete?

Polished concrete is created by following a multi-step process to turn an ordinary concrete slab into a smooth, glossy surface that reflects light effectively.

The process begins with grinding the concrete to remove imperfections, followed by honing with finer diamonds to achieve a smoother finish.

A densifier is then applied to harden the surface, enhancing durability. A sealant is used to achieve the desired gloss level.

Common finishes include a matte, satin, or high-gloss look, each suitable for different environments. For example, high-gloss finishes work well in stores to make them brighter, while matte finishes are usually chosen for homes to create a cozy atmosphere.

Process of Polishing Concrete

The process of polishing concrete involves grinding the surface with diamond-embedded abrasives followed by sealing to achieve a durable, shiny finish.

-

Begin with grinding, using a concrete grinder like the Husqvarna PG 450, which costs about $2,500. Start with coarse diamonds (40-80 grit) to remove imperfections, then move to finer grits (150-300) to smooth the surface.

-

After grinding, polish the concrete with 800-grit diamonds to improve shine.

-

Apply a penetrating sealer, which costs around $0.50-$1.50 per square foot, to protect the surface and bring out the gloss.

-

This entire process can range from $1.00 to $3.00 per square foot, depending on labor and material choices.

Advantages of Polished Concrete

Polished concrete offers many benefits, such as being very durable, having low upkeep expenses, and providing a shiny finish that improves indoor lighting.

A main benefit of polished concrete is that it doesn’t stain or scratch easily, which makes it great for busy places like shops or storage facilities.

For maintenance, occasional cleaning with a neutral pH cleaner suffices, reducing cleaning costs by up to 30%. Energy-saving LED lights can improve the shine of polished surfaces, brightening the area without raising electricity costs.

In business environments, this mix improves the design and helps reduce operating costs.

Maintenance of Polished Concrete

Maintaining polished concrete is simple. You mainly need to use pH-neutral cleaners and reseal it occasionally to keep it shiny.

For regular cleaning, opt for products like MARBLELIFE ENDURACRETE, which effectively removes dirt without damaging the finish.

Plan to reseal every 1-3 years, depending on how often the area is used and its state, using a high-quality sealant. Average costs for cleaning and resealing range from $0.30 to $0.50 per square foot.

Stay away from strong chemicals that might damage the surface; use a microfiber mop to clean without scratching. Consistent care will keep your polished concrete looking pristine year-round.

Stained Concrete Flooring

Stained concrete flooring is an attractive option for homeowners and businesses looking to add color and personality to their spaces with decorative finishes.

What is Stained Concrete?

Stained concrete is a process where color is added to concrete to make it look better and give it a strong, lasting finish.

There are two primary types of stains: acid-based and water-based.

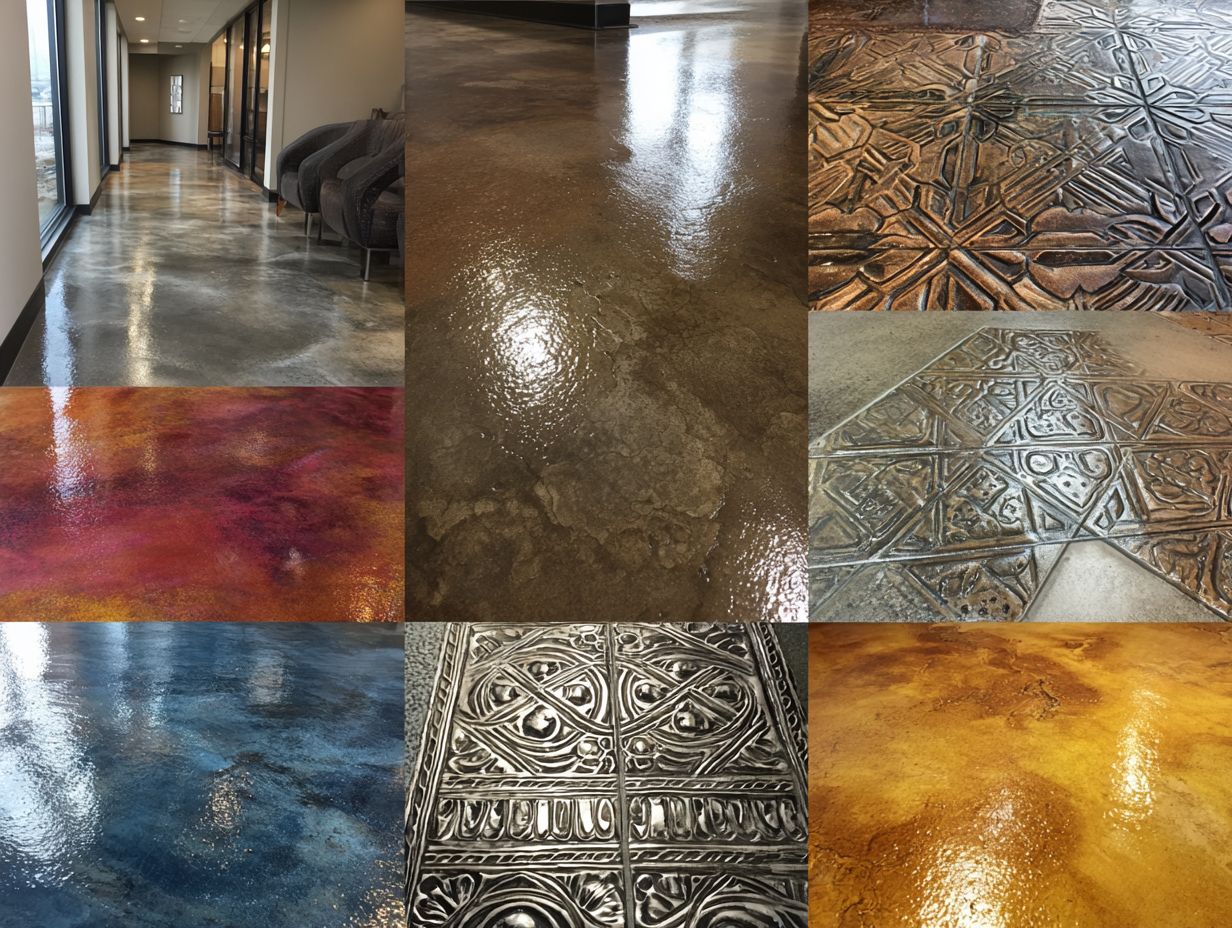

Acid-based stains create rich, variegated colors by reacting chemically with the concrete, resulting in earthy tones like browns and terracottas. Unlike other options, water-based stains provide many color choices, including bright and soft tones, making them suitable for decorative work.

Popular color palettes include warm earth tones for outdoor patios and cool grays or blues for contemporary interiors. Both stains improve the concrete’s appearance, but your choice should be based on the look you want and the environmental factors.

Types of Stains

Stained concrete can use different stains, like acid-based stains for deep, see-through colors and water-based stains for a wider range of colors.

Acid-based stains cost between $30 and $50 per gallon. They soak into the surface, creating bright, lasting colors that look like natural stone. In contrast, water-based stains (around $20-$40 per gallon) offer a wider selection of colors and are easier to clean up.

When selecting a stain, consider the desired finish: acid stains are ideal for a rustic, aged look, while water-based stains allow for customizable shades and finishes.

To make your concrete surface last longer, apply a sealer after staining.

Application Techniques

Application techniques for stained concrete vary, from simple applications using rollers for water-based stains to more controlled methods for acid stains.

For water-based stains, start by cleaning the surface thoroughly and allowing it to dry. Use a roller or sprayer for even coverage, applying 1-2 coats and letting each dry for at least two hours before applying the next.

Getting ready is important for acid stains. After cleaning, apply a primer if needed. Next, use a sprayer to put on the stain, keeping the nozzle a few inches away from the surface for uniform coverage.

Each method typically requires 4-6 hours, including drying time, for a professional finish.

Benefits of Stained Concrete

Stained concrete provides important advantages, such as improved visual appearance, choices for personal design, and being budget-friendly both for setting up and upkeep.

These advantages make stained concrete an excellent choice for both residential and commercial applications.

For instance, homeowners can achieve a unique look with various color options, while businesses appreciate the durability and low upkeep costs.

Stained concrete can increase property value by up to 15%, especially when used in outdoor patios or walkways.

Tools like concrete stain kits from brands such as Behr and Rust-Oleum simplify the application process, ensuring a professional finish even for DIY enthusiasts.

Care and Maintenance

Caring for stained concrete involves regular cleaning with pH-neutral cleaners and periodic resealing to maintain color and protect against wear.

To maintain stained concrete surfaces, clean them every 1-3 months using a pH-neutral cleaner, like Dawn or Concrobium.

Look at your stain every 1-2 years to check if it needs resealing. Use a high-quality sealer, such as the Eagle Natural Seal, which averages around $75 for 5 gallons.

This routine will keep the surface looking new and also make it last longer by stopping damage from spills and weather changes.

Stamped Concrete Flooring

Stamped concrete flooring looks like stone or brick and provides a strong and budget-friendly option for both outdoor and indoor spaces.

What is Stamped Concrete?

Stamped concrete is created by adding texture and color to freshly poured concrete, allowing for unique designs that replicate natural materials.

Common stamp designs include slate, cobblestone, and brick patterns, each offering a distinct aesthetic. To achieve these effects, begin by selecting a high-quality concrete mix and add pigments for color.

After pouring, while the concrete is still wet, apply the stamp, applying even pressure to create an imprint. Customization is possible by mixing patterns; for example, a brick design paired with a cobblestone border adds visual interest.

Think about using a release agent to stop sticking and make the pattern clearer, helping it last longer and stay strong outdoors.

Techniques for Stamping Concrete

Techniques for stamping concrete include using rubber molds and applying color hardeners, which allow for diverse decorative finishes.

To achieve the best results when stamping concrete, follow these steps:

- First, prepare your concrete surface by leveling and smoothing it.

- Use a stamp mat for patterns; make sure it bends easily to create detailed impressions.

- Next, apply a color hardener evenly across the surface before stamping, allowing ample time for absorption (usually about 30 minutes).

- Once the concrete is ready, position the stamp mat and apply firm, even pressure for clear impressions.

- Let the stamped concrete sit for at least 48 hours to make it last longer and look better.

Design Options for Stamped Concrete

Stamped concrete can be customized with various designs, colors, and textures, allowing homeowners to match their aesthetic preferences seamlessly.

Popular design options include textures like cobblestone and slate, which provide distinct looks suitable for patios or driveways.

When picking colors, think about the area around you. Natural shades go well with gardens, and bright colors can stand out as highlights.

Patterns like herringbone or basketweave can add visual appeal. It’s essential to also consider the usage of the concrete-areas with heavy foot traffic may benefit from textured surfaces to increase safety.

Talking to an expert can help you create a well-coordinated and attractive design that fits your area.

Advantages of Stamped Concrete

The advantages of stamped concrete include its cost-effectiveness compared to natural stone and its durability under high foot traffic conditions.

Stamped concrete can be customized with various patterns and colors to mimic the look of natural stone, brick, or even wood, enhancing its aesthetic appeal.

For example, applying a basic stamp design and a stain can change regular concrete into an impressive patio that looks like costly stonework.

To keep it in good shape, simply put on a sealant every few years.

Homeowners can expect stamped concrete to be about 20-30% cheaper than natural stone while providing excellent performance in both beauty and resilience.

Maintenance of Stamped Concrete

Stamped concrete needs regular sealing and cleaning to stop it from fading and to keep its decorative look lasting long.

To maintain your stamped concrete, clean it at least twice a year using a pH-balanced cleaner and a stiff-bristle brush to remove dirt and grime.

After cleaning, let the surface dry completely before applying a quality sealer such as WetLook or Shine-Up, which protect against stains and UV rays.

Look for any cracks or damage yearly, and repair any issues immediately. Addressing these maintenance tasks regularly can significantly extend the life and appearance of your stamped concrete surfaces.

Comparing Polished, Stained, and Stamped Concrete

Consider the advantages and disadvantages of polished, stained, and stamped concrete to determine which is best for your project.

Cost Comparison

The cost of concrete flooring varies significantly, with polished concrete averaging $3-$8 per square foot, stained concrete ranging from $2-$4, and stamped concrete priced at $8-$12.

Additional materials can influence these costs. For polished concrete, budgeting for a grinder and sealant might add $1-$2 per square foot. Stained concrete often requires a sealer and can incur an extra $0.50-$1 for a quality finish.

Meanwhile, stamped concrete projects usually include costs for stamps and release agents, which can total around $1-$3 per square foot. To get the most out of your investment, think about how long it will last and the ongoing costs. Polished concrete usually lasts longer and needs less maintenance, making it a reliable choice in the long run.

Durability and Longevity

Durability varies among concrete types; polished concrete can last up to 20 years with minimal maintenance, while stamped concrete may require more frequent upkeep.

For instance, polished concrete surfaces are ideal for commercial spaces with high foot traffic as they resist scratches and staining. You need to clean the floor often and apply a new sealant every few years.

Unlike other materials, stamped concrete, which is commonly used for patios and driveways, often needs resealing every 1-3 years to keep its color and prevent damage, especially in areas with harsh weather.

Therefore, choosing the right type of concrete based on usage and maintenance preferences can significantly impact long-term satisfaction and costs.

Design Versatility

Concrete flooring can be designed in different ways, including smooth polished surfaces, colorful stained patterns, and textured stamped finishes.

For a modern look, polished concrete works beautifully in minimalist spaces, reflecting light and enhancing the sense of openness.

On the other hand, stained concrete gives a cozy and unique feel, making it ideal for homes or cafes.

Texture can be added with stamped finishes, resembling natural stone or wood, perfect for outdoor patios.

Consider integrating decorative aggregates for visual interest.

Pair these styles with matching decor-like metal fixtures for polished surfaces or earthy tones for stained varieties-to create a cohesive design that emphasizes your unique aesthetic.

Frequently Asked Questions

What are the different options for concrete flooring?

The three main options for concrete flooring are polished, stained, and stamped. Each option provides a unique look and has its own benefits.

How is polished concrete flooring achieved?

Polished concrete flooring is achieved by grinding and honing the surface of the concrete until it becomes smooth and shiny. This process also involves applying a sealant to protect the surface.

Can concrete flooring be stained?

Yes, concrete floors can be colored in different shades and designs to create a one-of-a-kind appearance. Staining can be done before or after the concrete is polished.

What is the process for stamping concrete flooring?

Stamping concrete flooring involves using specialized stamps to create patterns and textures on the surface of the concrete. This is typically done before the concrete is polished and sealed.

What are the advantages of polished concrete flooring?

Polished concrete flooring is durable, low-maintenance, and can be customized with different levels of shine. It is also a cost-effective option compared to other types of flooring.

How long does it take to install stamped concrete flooring?

The installation time for stamped concrete flooring varies depending on the size of the area and the complexity of the design. On average, it can take anywhere from 2-5 days to complete the installation process.