VOC Emissions in Flooring – Standards and Health

Contents

- Introduction to VOC Emissions in Flooring

- Sources of VOC Emissions in Flooring

- Health Effects of VOC Exposure

- Regulatory Standards for VOC Emissions

- Flooring VOC Emissions and Compliance Data

- Testing and Measurement of VOC Emissions

- Reducing VOC Emissions in Flooring

- Future Trends in VOC Emission Standards

- Frequently Asked Questions

- What are VOC emissions in flooring?

- What are the standards for VOC emissions in flooring?

- Why are VOC emissions in flooring a health concern?

- How can I tell if a flooring product meets VOC emission standards?

- Are there any health benefits to choosing low VOC flooring?

- What can I do to reduce VOC emissions from my flooring?

Introduction to VOC Emissions in Flooring

Key Takeaways:

Definition of VOCs

VOCs are organic chemicals that have a high vapor pressure at room temperature, including compounds like formaldehyde and benzene, known for their adverse health effects.

Common sources of VOCs in buildings include paints, varnishes, cleaning products, and certain carpeting materials.

For instance, formaldehyde is often released from pressed wood products, while benzene can emanate from tobacco smoke and vehicle emissions nearby.

To mitigate exposure, consider using low-VOC or VOC-free paints, ensuring proper ventilation during renovations, and utilizing air purifiers equipped with activated carbon filters.

Regularly replacing air filters can also significantly reduce indoor air pollution, contributing to a healthier living environment.

Importance of Studying VOC Emissions

Knowing about VOC emissions is important to create air quality rules that safeguard people’s health, especially in homes and businesses.

Studying VOC emissions helps identify harmful compounds, such as benzene and formaldehyde, that contribute to respiratory issues and other health problems.

Regulations demand meeting certain limits to reduce exposure. Tools like air quality monitors and data analysis software can help businesses track emissions.

For example, companies can use the EPA’s Air Quality Modeling System to make sure they follow guidelines. By following these rules, organizations protect public health, prevent fines, and improve their reputation in the community.

Sources of VOC Emissions in Flooring

VOCs can come from different parts of flooring, such as the substances it’s made of, how it’s produced, and how it’s put in place. For those concerned about safety and health implications, our guide on vinyl flooring VOC emissions offers comprehensive insights into managing these emissions effectively.

Types of Flooring Materials

Different flooring materials emit varying levels of VOCs, with laminate and vinyl flooring often cited for higher emissions due to their synthetic components.

In contrast, low-VOC alternatives like bamboo, cork, and reclaimed hardwood offer safer options for indoor air quality.

For example, bamboo flooring typically carries an E0 rating, signifying very low emissions. Cork is another excellent choice; its natural properties help reduce VOC levels while providing added insulation. Learn more about cork flooring’s sustainability and comfort in our benefit-focused guide.

When selecting flooring, consider materials certified by recognized programs, ensuring compliance with safety standards. Check for labels like GreenGuard or FloorScore to confirm you’re selecting eco-friendly and safe choices.

Manufacturing Processes

Producing flooring can cause high levels of harmful emissions, particularly when using adhesives and finishes that contain formaldehyde and other toxic chemicals.

Manufacturers can use different methods to reduce these emissions.

- Utilizing low-VOC adhesives and finishes, certified by standards such as ASTM D5116, significantly reduces harmful outputs.

- Switching to water-based products is also effective, as they typically contain fewer volatile compounds.

- Implementing better ventilation during the application process can help disperse VOCs quickly, enhancing air quality.

- Checking and testing VOC levels regularly helps meet legal requirements, keeps workers and customers safe, and preserves product quality.

Installation and Maintenance Practices

Installation and maintenance practices, including the use of certain adhesives and cleaning protocols, can exacerbate VOC emissions in indoor environments.

To minimize VOC emissions, consider using low-VOC or VOC-free adhesives such as those available from brands like Sika or Titebond.

Implement proper ventilation during installation; opening windows or using exhaust fans can significantly reduce indoor pollutant levels.

Regular cleaning with eco-friendly products, like those from Method or Seventh Generation, also helps maintain a healthier indoor environment.

Timely maintenance checks can prevent leaks and deterioration that often release hidden VOCs, ensuring a safer living space for you and your family.

Health Effects of VOC Exposure

Being around VOCs can cause health problems, including temporary irritation, long-term breathing issues, and serious illnesses like asthma.

Short-term Health Effects

Short-term exposure to VOCs can result in symptoms such as headaches, dizziness, and respiratory irritation, often exacerbated by high levels of benzene exposure.

Research indicates that nearly 30% of people exposed to high levels of VOCs experience headaches and 12% report dizziness.

Studies show that even short bouts of exposure can irritate the respiratory system, leading to coughing or wheezing. For instance, exposure to formaldehyde at levels above 0.1 ppm is linked to significant respiratory discomfort.

To reduce these effects, make sure to ventilate enclosed spaces well, use air purifiers with activated carbon filters, and regularly check indoor air quality with devices like Aeroqual or AirThings.

These steps can dramatically lower VOC concentrations and protect your health.

Long-term Health Effects

Long-term exposure to VOCs may lead to chronic health conditions, including respiratory diseases and increased cancer risk due to formaldehyde emissions.

Research indicates that individuals exposed to high levels of VOCs are at a greater risk for developing conditions such as asthma, chronic obstructive pulmonary disease (COPD), and various cancers.

For instance, a study published in the Journal of Exposure Science and Environmental Epidemiology revealed a significant correlation between residential VOC levels and respiratory issues among occupants.

To reduce exposure, consider using air purifiers equipped with activated carbon filters, ensuring good ventilation, and choosing low-VOC paints and cleaners.

Implementing these strategies can significantly mitigate health risks associated with VOCs.

Vulnerable Populations

Certain populations, including children and the elderly, are particularly vulnerable to the health effects of VOC exposure, often exacerbated in poorly ventilated spaces.

These groups often live in conditions that increase their exposure to volatile organic compounds (VOCs), such as aging homes with outdated materials or institutions like schools and nursing homes.

For instance, children may spend considerable time in classrooms where cleaning products and paints are used frequently.

To reduce risks, it’s important to use low-VOC paints or ventilation systems that clean indoor air. Regularly checking HVAC systems helps keep air clean and lowers VOC levels, providing safety for sensitive groups.

Regulatory Standards for VOC Emissions

Different rules govern VOC emissions, with groups like the California Air Resources Board and the Green Building Council Australia creating strict guidelines.

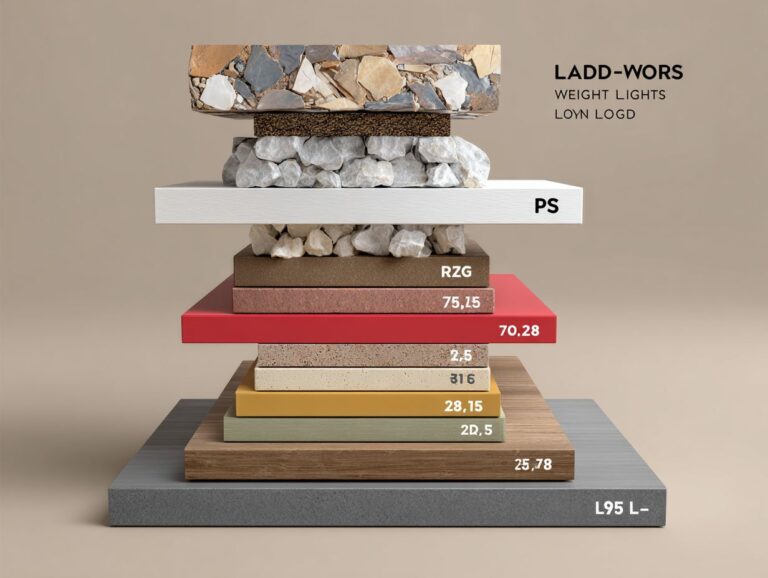

Flooring VOC Emissions and Compliance Data

Flooring VOC Emissions and Compliance Data

VOC Concentration Levels: VOC Levels

The Flooring VOC Emissions and Compliance Data offers essential information about the amount of volatile organic compounds (VOCs) released by flooring materials. VOCs are significant contributors to indoor air pollution, affecting human health and environmental quality. Knowing these levels is important to meet health and environmental rules.

VOC Concentration Levels are measured in milligrams per cubic meter (mg/m), providing a quantitative assessment of air quality concerning flooring emissions. This dataset categorizes VOC levels into four distinct ranges:

- Low VOC (0.3 mg/m): Flooring materials that emit VOCs at this level are considered safe and preferable, especially for indoor environments. Low VOC emissions contribute to better air quality, minimizing health risks such as respiratory issues and allergic reactions.

- Acceptable VOC (0.5 mg/m): Materials in this range are generally regarded as compliant with most health and safety standards. While slightly higher than low VOC levels, they remain within limits deemed acceptable for residential and commercial use, balancing performance and environmental impact.

- Marginal VOC (1.0 mg/m): Emissions at this level may warrant caution, as prolonged exposure could lead to potential health concerns. These materials might be suitable for certain applications but could require ventilation or other measures to mitigate exposure.

- High VOC (3.0 mg/m): Flooring materials with high VOC emissions pose significant concerns for indoor air quality and health. It is usually advised not to use these materials unless there are systems to control air, like improved ventilation.

The categorization of VOC levels into these defined ranges allows manufacturers, consumers, and regulators to make informed decisions regarding flooring options. Choosing materials with low VOC levels can greatly improve indoor air, leading to healthier homes and workplaces. Meeting VOC standards meets legal rules and shows dedication to protecting the environment and maintaining public health.

International Standards

International standards, such as ISO 16000, guide countries in assessing VOC emissions and establishing benchmarks for compliance in building materials.

These standards require manufacturers to perform thorough testing to make sure products release volatile organic compounds (VOCs) within allowed limits.

For example, a company might implement ISO 16000-3, which measures formaldehyde emissions from wood-based products. Meeting these standards improves air quality and makes products more appealing to buyers by showing a commitment to the environment.

Following these rules can reduce the chances of legal problems from not following them, helping to create a more environmentally friendly way of producing goods. Using tools like emission testing labs can make this process easier, ensuring evaluations are correct each time.

National Standards

In the U.S., the Environmental Protection Agency (EPA) sets national standards for VOC emissions, focusing heavily on formaldehyde and other hazardous materials.

These standards encompass regulations such as the National Emission Standards for Hazardous Air Pollutants (NESHAP), which limit emissions during industrial processes.

Enforcement is carried out through periodic inspections and reporting requirements, ensuring compliance. For example, facilities must use monitoring technologies like Continuous Emissions Monitoring Systems (CEMS) to track their emissions instantly.

Companies face penalties if they exceed permissible limits, reinforcing accountability. Organizations often use compliance tools like Envirosuite to simplify following rules and managing reports.

State and Local Regulations

State and local regulations can impose stricter VOC emission limits, with agencies like the South Coast Air Quality Management District requiring compliance for flooring products.

For instance, while the federal standards set by the Environmental Protection Agency (EPA) might allow for higher VOC levels, California’s regulations can necessitate products containing 0.05 to 0.1 grams per liter.

Manufacturers need to test batches to meet rules, using tools like gas chromatography for exact measurement. Keeping detailed records of compliance testing and product formulations can safeguard against surprise inspections.

If companies do not follow local rules, they could face large fines or have their products banned.

Testing and Measurement of VOC Emissions

Accurate testing and measurement of VOC emissions are important for meeting safety rules, using methods set by organizations like ASTM.

Common Testing Methods

Common testing methods for VOC emissions include chamber tests and gas chromatography, used to analyze emissions from flooring materials under controlled conditions.

Chamber tests involve putting materials in closed spaces to track the level of volatile organic compounds (VOCs) over time, giving information on emissions for extended periods.

Gas chromatography, on the other hand, separates and quantifies different volatile compounds, allowing for detailed chemical analysis.

Chamber tests are useful for imitating normal conditions, while gas chromatography works well for identifying specific VOCs.

Industry professionals usually combine these methods to collect full data and report emissions precisely for reliable VOC readings.

Interpreting Test Results

To read VOC test results, you need to know the compliance limits established by regulations, which are often given in parts per million (PPM).

To effectively analyze VOC test results, start by identifying the specific regulatory limits relevant to your industry, such as those outlined by OSHA or EPA.

For example, if a threshold of 200 PPM is set for a particular chemical, any reading above this indicates non-compliance. It’s essential to regularly compare your results to these limits, keeping track of historical data trends.

Using software tools like LabArchives can show this data over time, helping to guide decisions on needed changes.

Reducing VOC Emissions in Flooring

Reducing VOC emissions in flooring involves choosing low-VOC materials, improving ventilation, and maintaining regular cleaning routines.

Choosing Low-VOC Materials

Opting for low-VOC materials, such as flooring with an E0 rating and certified sustainable options, can significantly reduce indoor air pollution.

Begin by searching for certifications such as Green Label Plus or FloorScore. These show that the product has passed thorough tests for VOC emissions.

Consider products such as bamboo flooring from Cali Bamboo, which offers E0-rated options and is sustainably sourced. Another great choice is laminate from Pergo, known for its low emissions and durability.

Cork flooring from naturalcork.com is another eco-friendly option that provides insulation and comfort.

Visit local showrooms to check out materials and request samples to see if they match your style and work requirements.

Improving Ventilation

Improving ventilation effectiveness through outdoor air systems and advanced air filtration can drastically cut VOC levels in indoor environments.

To improve ventilation in buildings, think about using both mechanical systems and natural methods. For instance, installing energy recovery ventilators (ERVs) helps exchange stale indoor air with fresh outdoor air while minimizing energy loss.

Complement this with operable windows and strategically placed vents for natural airflow. It’s important to clean filters and check for any duct blockages every three months.

By integrating these methods, you can create a healthier indoor environment while improving air quality.

Best Practices for Installation

Implementing best practices during flooring installation, including proper moisture management and choosing appropriate cleaning protocols, minimizes VOC emissions.

Picking adhesives with low volatile organic compounds is important, along with managing moisture and cleaning. For example, using water-based adhesives instead of solvent-based can significantly decrease emissions.

Schedule installations during off-peak hours, ensuring that occupants are not present to reduce exposure. This approach protects indoor air quality and provides enough time for materials to set when no one is in the building.

Moisture meters can accurately measure conditions, ensuring materials bond properly and decreasing the risk of harmful chemicals being released during installation.

Future Trends in VOC Emission Standards

Upcoming trends suggest stricter VOC emission rules due to new developments in flooring materials and possible changes in regulations at all levels.

Innovations in Flooring Materials

Innovations in flooring materials, such as eco-friendly products made from recycled content or bio-based materials, are reducing VOC emissions significantly.

For instance, bamboo flooring, like MOSO Bamboo, is a rapidly renewable resource producing low VOC levels. Similarly, cork flooring products from Amorim are made from harvested cork oak bark, providing excellent insulation and a natural resistance to mold and mildew.

Luxury vinyl tiles (LVT), such as those by Karndean, are designed using advanced manufacturing processes that decrease VOC emissions. These options improve indoor air quality, last a long time, and look great, making them ideal for environmentally-friendly building projects.

Potential Policy Changes

Potential policy changes may lead to stricter VOC regulations, pushing manufacturers towards greater transparency and the development of sustainable practices.

Manufacturers will have to change by spending on cleaner technologies and carrying out regular emissions testing. For example, adopting water-based paints instead of solvent-based options can significantly reduce VOC emissions.

Companies could use tools like EcoStruxure from Schneider Electric to keep an eye on compliance instantly. By following these steps, manufacturers comply with rules and strengthen their market standing.

Consumers, in turn, may benefit from safer products and a broader selection of eco-friendly options.

Frequently Asked Questions

What are VOC emissions in flooring?

VOC emissions in flooring refer to the release of volatile organic compounds (VOCs) from various flooring materials into the air. These compounds are harmful to human health and can have negative effects on indoor air quality.

What are the standards for VOC emissions in flooring?

The standards for VOC emissions in flooring are set by various organizations, including the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB). These standards set limits on the VOCs that flooring materials can release to protect people’s health and the environment.

Why are VOC emissions in flooring a health concern?

VOC emissions in flooring can have negative effects on human health, such as respiratory irritation, headaches, and dizziness. Prolonged exposure to high levels of VOCs can also lead to more serious health issues, including cancer and damage to the central nervous system.

How can I tell if a flooring product meets VOC emission standards?

You can look for certifications or labels on flooring products that indicate they meet VOC emission standards. These may include the Greenguard or FloorScore certification, which are both recognized by the EPA and CARB.

Are there any health benefits to choosing low VOC flooring?

Yes, low VOC flooring can have health benefits as it reduces the amount of harmful compounds released into the air. This can improve indoor air quality and reduce the risk of health issues caused by VOC exposure.

What can I do to reduce VOC emissions from my flooring?

To reduce VOC emissions from flooring, you can choose low VOC flooring materials, increase ventilation in your home or workplace, and regularly clean and maintain your flooring. It is also important to follow proper installation and ventilation practices when installing new flooring.